Noise is generally considered low quality, unwanted sound. The primary selection criterion for a fan is based not on its acoustical characteristics but on its ability to move the required amount of air against the required pressure. In addition, the fan must do so at a reasonable initial cost (it also may be required to handle dust-laden air, to resist abrasion and/or corrosion, to have a type of construction that can be repaired easily in the field, to withstand high temperature, etc). Once these requirements have been met, the type, size and speed of the fan are completely determined then the noise characteristics of the fan also are determined. In most cases it is not practical to substitute a fan, which generates less noise, since a quieter design of the same type probably will not meet the other operating specification for the fan. Therefore, sound power levels generated by a correctly selected fan must be accepted as the sound power levels to be used in acoustical design calculations. There are three categories of fan noise viz:

- Aerodynamic generated noise is characterized by a continuous broadband frequency spectrum with a superimposed tone. The tone is typically objectionable when it becomes 4-6dB louder than the rest of the spectrum. The tone can be the blade frequency, which is a function of the fan type. It can become very objectionable when system effects and various controls cause it to rise higher than normal. Additional causes include turbulence, high velocities, and instabilities due to pulsation and surge. The probable causes of aerodynamically generated noise is blade frequency, system effects, damper stall, surge, hunting, or turbulence, The noise characteristics associated with aerodynamic noise are pure tone, whistles, rumble, pulsating, hiss or beating.

- Mechanical noise due to rotation and has a different sound quality and characteristic. It has a metallic sound caused by metal-to-metal contact. This contact may be constant or intermittent. The probable causes of mechanical noise loose fittings or problems with bearings, sheaves, shaft or Vbelts. The noise characteristics associated with mechanical noise are rattling, scraping, banging, screeching or clicking.

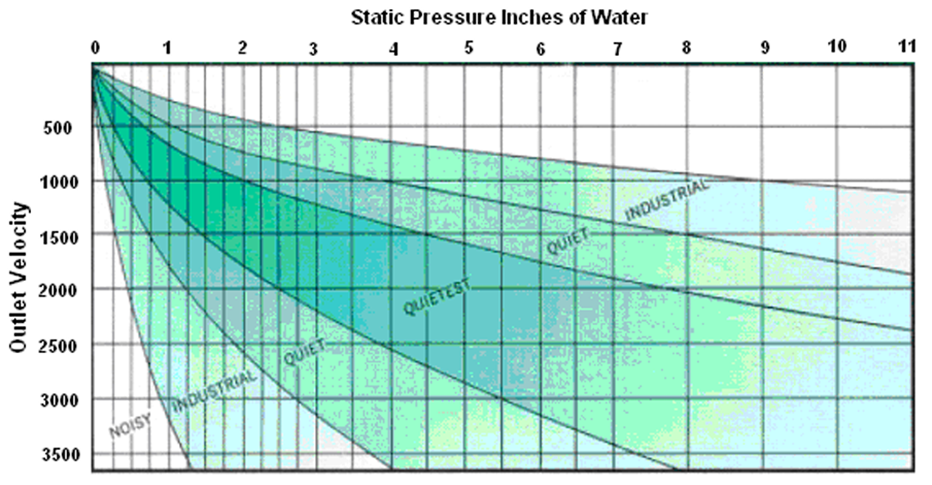

- Electrically generated noise is a function of motors, relays, controls or unbalanced line voltages into the motor. Sometimes improperly matched VFD and motors can cause a substantial increase in the motor noise due to imperfect sine wave simulation. The noise characteristics associated with electrical noise are hum, whine or chatter. Broadly, fan noise is a function of fan design, volume flow rate of air, total pressure, and efficiency. After making a decision on the proper type of fan for a given application, the best selection of a specific fan must be based on efficiency. The most efficiently operating fan will also be the quietest fan. Fan noise is an important consideration, particularly when the fan is located near occupied space and is operating against a static pressure of 1” or greater. The following table provides a quick method for considering the degree of quietness when selecting a air blower.

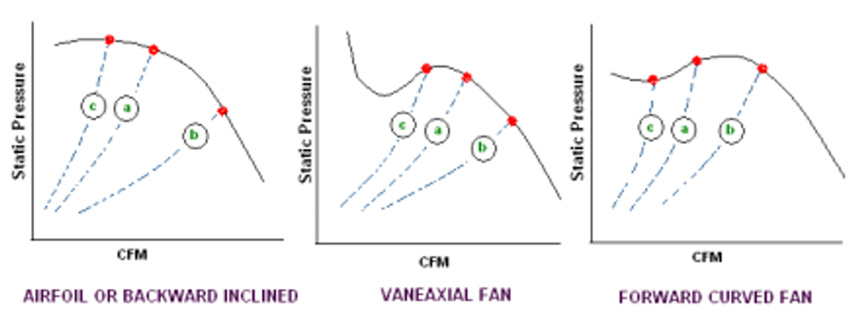

There are operating characteristics typical to various generic fan types, which make them more or less suitable to variable volume operation (having smaller or larger range on the fan curve with relative operation efficiency). The shape of each curve gives some indication of sensitivity to the system effects, such as inlet and discharge conditions and potential noise. Each of the fan illustrations in the figure below shows a) system resistance intersecting the fan curve at “maximum efficiency point” (quiet operation), b) system resistance intersecting the fan curve in the region of “rotating stall” (low frequency rumble) and c) system resistance in the “surge” region (low frequency fluctuating noise). On each of these fan curves, moving further out on the fan curve ( to the right of the maximum efficiency) also increases noise levels, but predominantly in mid and high frequencies and at blade passage frequency, which varies with the rotational rate according to the following equation:

BPF = (n/60) * N

Where

BPF = blade passage frequency

n = fan wheel revolutions per minute (rpm)

N = number of impeller blades Note that the blade passage frequency can be perceived as tone. If it coincidently occurs within a frequency span of fan noise spectrum that is prominent, it can emphasize the tonality of an otherwise relative smooth fan noise spectrum. Harmonics and sub-harmonics are possible at the multiples of the blade passage frequency, but at lower amplitude (sound level).

Related Posts:

Common maintenance tasks on fan systems include: ■ Periodic inspection of all system components ■ Bearing lubrication and replacement ■ Belt tightening and replacement ■ Motor repair or replacement ■ Fan cleaning.

◆ Basic Principle Like most other rotating machinery, fans experience wear and require periodic maintenance and repairs. Dynamic surfaces in bearings and belt drives degrade over time.Fan blade surface…